The Vankel/ Varian/ Agilent Tap Density Tester is used to measure the tapped or packed volumes of powders, as well as granulated or flaked materials. It works with a variety of graduated cylinders, from 10 to 500 ml with either a standard or funnel top. This is important since changes in the tapped density of raw materials can affect their performance during the manufacturing process. For example, powders which do not meet the normal incoming QC tapped density specification might tend to clog tablet presses and disrupt the manufacturing process.

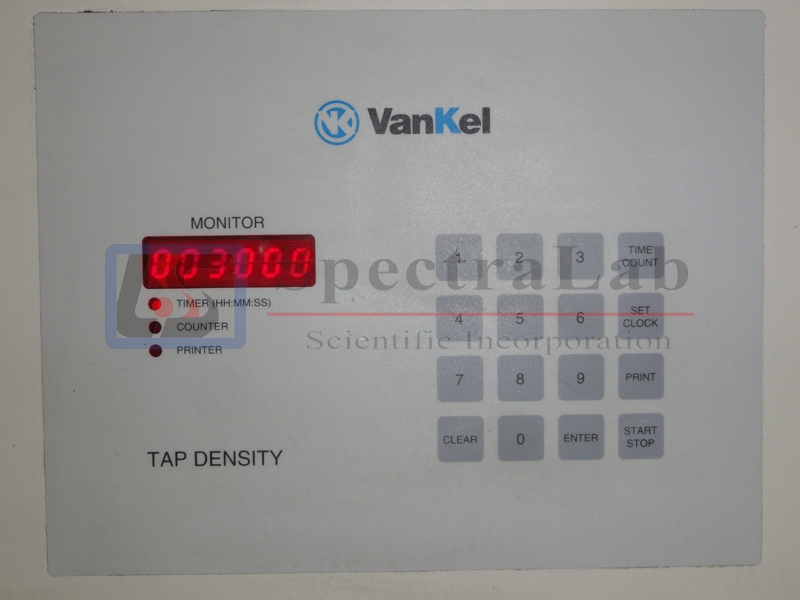

The tapping action is generated by a rotating eccentric camshaft which lifts the platform and allows it to drop back to its original position. A shoulder machines into the cam causing the platform to rotate approximately 5 – 15 times per minute, ensuring an evenly packed surface. The drive motor is synchronous with the AC line frequency for the highest possible speed, accuracy, and precision. It is geared to provide a nominal speed of 300 taps per minute.