The Agilent 1260 Infinity Bio-inert High Performance Autosampler features an increased pressure range (up to 600 bar) enabling the use of today’s column technology (sub-two-micron narrow bore columns) with the Agilent 1260 Infinity LC System. Increased robustness is achieved by optimized new parts, high speed with lowest carry-over by flow through design, increased sample injection speed for high sample throughput, increased productivity by using overlapped injection mode and flexible and convenient sample handling with different types of sample containers, such as vials and well plates. Using 384-well plates allows you to process up to 768 samples unattended.

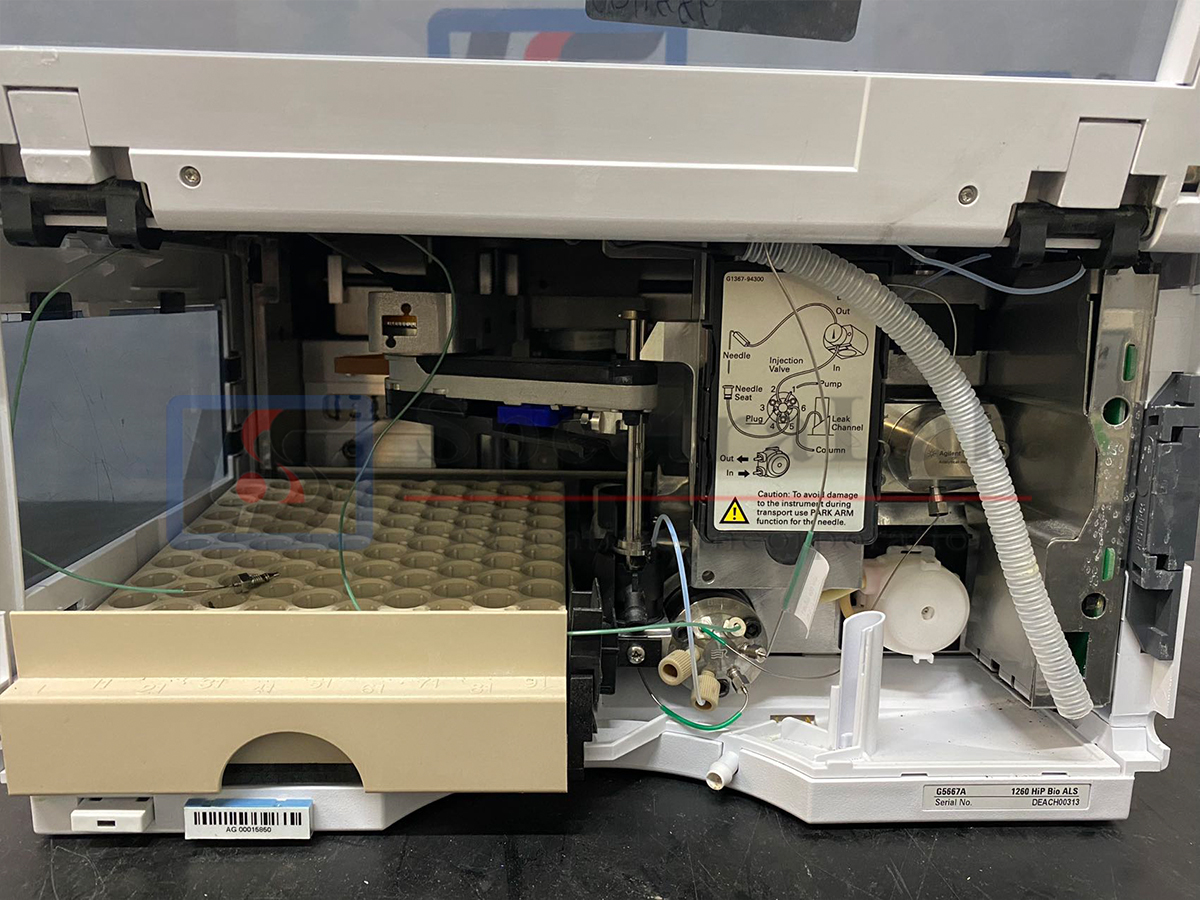

The Autosampler transport mechanism uses an X-Z-theta robot to optimize the positioning of the sampling arm on the well plate. Once the sampling arm is positioned over the programmed sample position, the programmed sample volume is drawn by the metering device into the sampling needle. The sampling arm then moves to the injection position where the sample is flushed onto the column.

The Autosampler employ a vial/plate pusher mechanism to hold down the vial or the plate while the needle is drawn back from the sample vessel (a must in the case a septum is used). This vial/plate pusher employs a sensor to detect the presence of a plate and to ensure accurate movement regardless of plate used.

All axes of the transport mechanism (x-,z-,theta-robot) are driven by stepper-motors. Optical encoders ensure the correct operation of the movement.

The standard metering device provides injection volumes from 0.1 – 100 µL. The entire flow path including the metering device is always flushed by the mobile phase after injection for minimum internal carry-over.

An additional needle flush station with a peristaltic pump is installed to wash the outside of the needle. This reduces the already low carry-over for very sensitive analysis.

The bottle containing the mobile phase for the wash procedure will be located in the solvent bottle cabinet. Produced waste during this operation is channeled safely away through a waste drain.

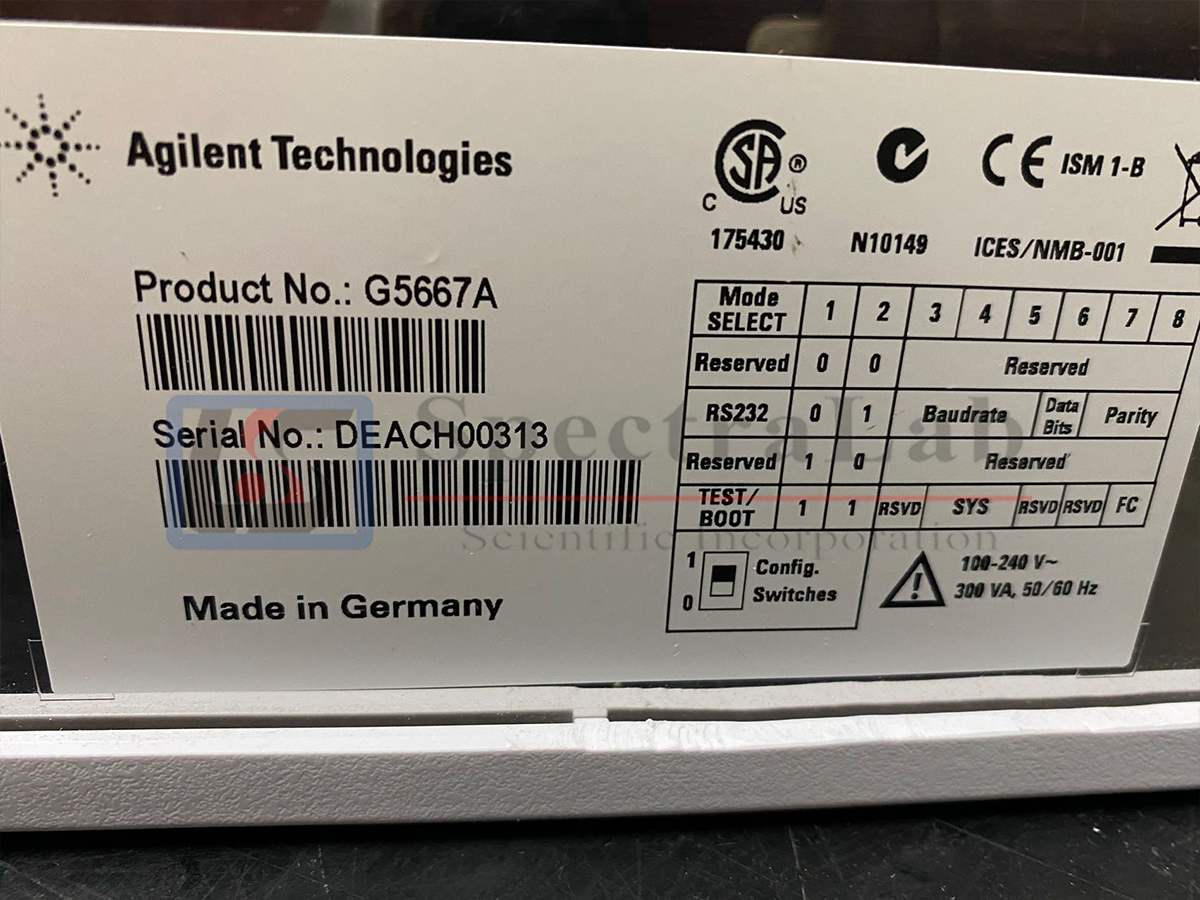

Specifications:

– Injection range: 0.1 to 100 μL in 0.1 μL increments

– Pressure range: Up to 600 bar (8700 psi)

– Sample viscosity range: 0.2 to 5 cp

– Injection cycle time: Typically < 17 s using the following standard conditions: Default draw speed: 100 μL/min. Default eject speed: 100 μL/min. Injection volume: 5μL

– Carry-over: Typically <0.004 %

– pH range: 1 to 13

– Dimensions (H x W x D): 20 x 34.5 x 44 cm (8” x 13.5” x 17”)

– Weight: 15.5 kg (35 lbs)