This unit is for parts only condition, sold as it is.

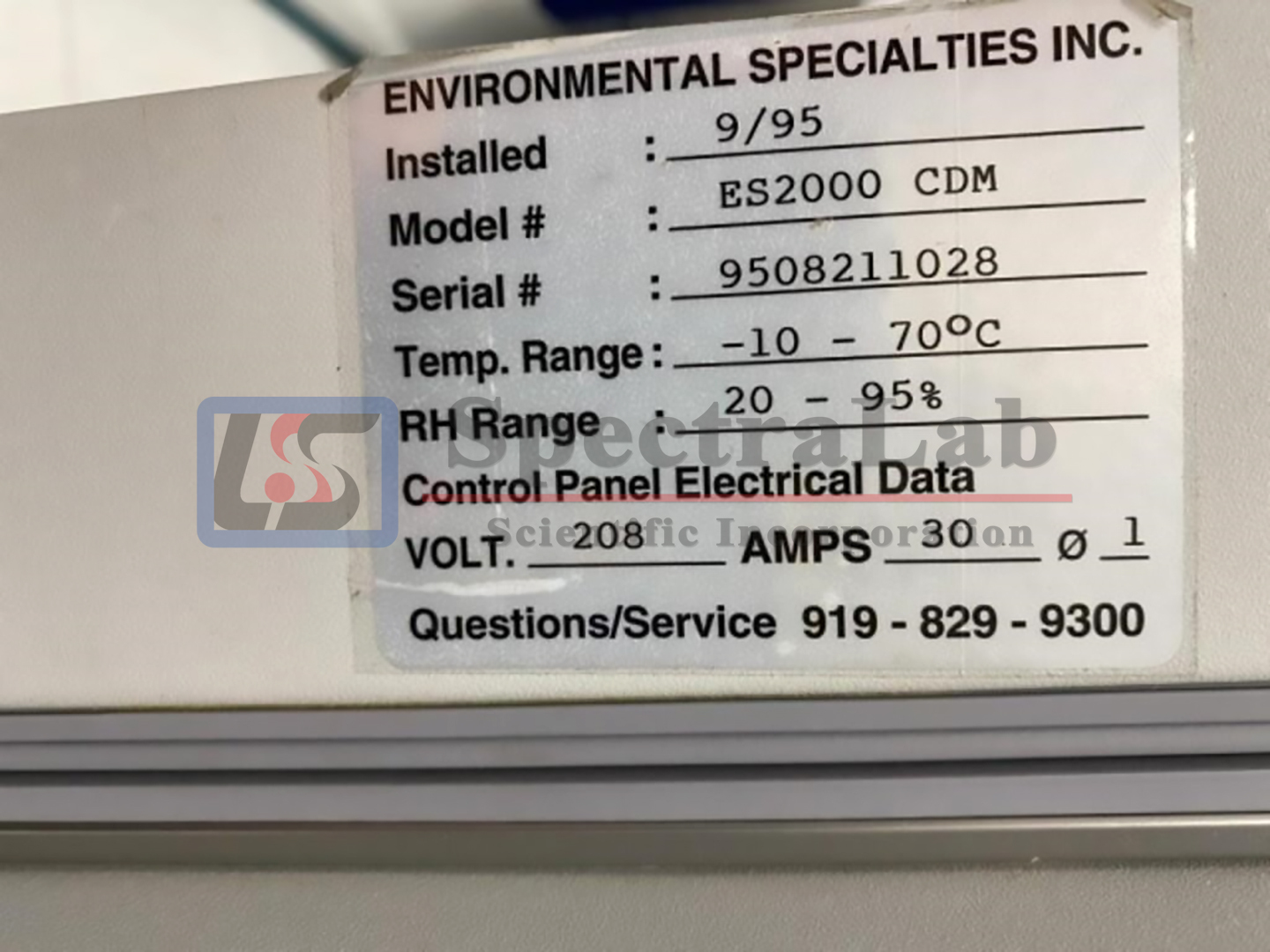

Series Model Serial Number: #9508211028

Conditioning System

Our precise air control system ensures conditioned air is distributed uniformly across your product shelves. A stainless steel impeller moves the air through the conditioning components within the enclosed plenum. Air is then distributed and returned through the plenum’s side wall ports which are specifically arranged for maximum uniformity and efficient thermal transfer. The conditioning system features include:

- Temperature control to within ±0.2°C

- Relative humidity control to within ±0.7%RH

- Temperature uniformity capability down to ±0.3°C *

- Relative humidity uniformity capability down to ±3.0%*

* Note: See the SPECIFICATION section for uniformities applicable to doublewide (74c.f.) and triplewide (114c.f.) models.

Cabinet Construction

Our doublewall chamber construction provides you with years of continued, trouble-free use. The polished 304 #3 finish interior is heliarc-welded at the seams to form a hermetic seal which prevents moisture from migrating into the insulation. Each chamber size is proportioned to allow you ease of passage through a standard doorway. Construction features and options include:

- Heavy-gauge stainless steel interior with scratch resistant enamel on exterior of cabinet.

- Closed-cell urethane insulation for superior high/low temperature stability and minimal heat transfer. The door is also completely foamed for thermal performance and rigidity.

- Heavy-duty door hinges, full peripheral magnetic door gaskets and positive action latch with a lock to maintain a secure, uniform seal.

- Removable stainless steel plenum cover and wall air chases for ease in cleaning and maintenance.

- Heavy duty 2′ casters (on floor models) and adjustable leveling feet for ease in installation.

Product Shelving

Solid, reinforced stainless steel shelves are provided standard with each chamber, with additional shelves available upon request. The shelves slide in via shelf brackets which are easily relocatable on 1 1/2′ centers.* The location and quantity flexibility can accommodate alternative inventory systems, racks, carts or other load requirements. Each shelf can support up to 130 lb. of distributed load, and offers over 6 sq. ft. of usable area.

*While the spacing is variable on 1 1/2′ increments, we recommend a minimum of 3′ center-to-center spacing on shelf locations.

Proportional Refrigeration System

BES incorporates a proportional liquid/hot gas refrigeration design to maintain close tolerance temperature control and rapid acceleration to your setpoint. The compressor life is extended by modulating refrigerant flow as required. The proportional refrigeration system features are as follows:

- Air-cooled, hermetically sealed compressor with environmentally safe, non-toxic, CFC-free refrigerants. Optional water-cooled units are available.

- Expansion valve refrigeration control provides higher heat removal capacity than conventional capillary tube designs and provides immediate response to added heat loads.

- Automatic time or temperature actuated hot gas/electric defrost provide with “intelligent” adaptive defrost timer; time or temperature initiated and time or temperature terminated. By sensing chamber coil temperature, the timer allows for minimum temperature rise due to a defrost cycle.

Temperature and Humidity Controls

Our backlit, alphanumeric LCD color touchscreen display provides operator access to all system parameters through intuitive, Windows® style drop down menus. The 7” display is compatible with low to high room light levels. Menu selections and on-screen instructions with on screen help are of sufficient detail to allow for typical day-to-day use without reference manuals.

Features include:

- Temperature display configuration in °C or °F.

- Relative humidity configuration in % RH (if applicable).

- Precision, platinum RTD temperature sensor calibrated per NIST traceable standards.

- Solid-state variable capacitance humidity sensor calibrated per NIST traceable standards.

Humidification/Dehumidification

Our solid state controlled electric steam humidifier offers additive humidity, and our ‘latent coil’, or desiccant drier, models offer lower humidity control. High and low humidity capability is dependent on your model selection. See the HUMIDITY PERFORMANCE CURVE sheet for specific ranges on each model. The humidity system features:

- High output vapor generator providing precisely controlled humidification. A fully stainless steel tank (type 316), incoloy heater and float switch actuated solenoid fill system are notable features.

- Separate ‘latent coil’ design offering mid-range dehumidification capability.

- Compressed air tower (CDM-AT) or desiccant-wheel drier (CDMD) models offering extended low range dehumidification capability.

- “Intelligent” enabling / disabling of humidification and dehumidification. Humidification is disabled below freezing, and dehumidification is disabled at factory-selected conditions where drying is not required.

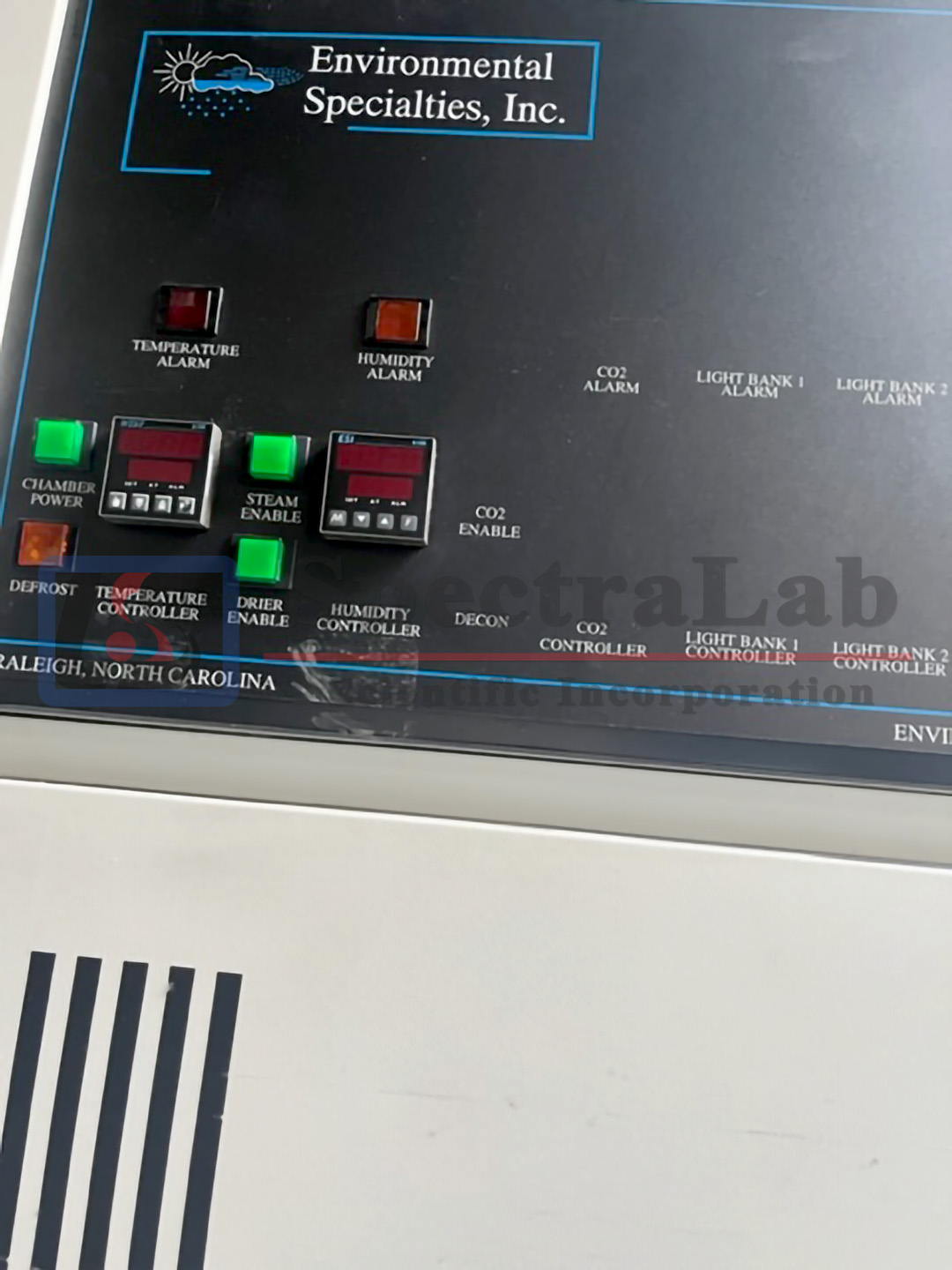

Alarm/Monitoring System

Our control panel features independent, adjustable high/low visual and audible alarms for temperature and humidity. Automatic alarms disable specific controlled devices (heaters, blowers, steam generators, etc.) The alarm monitoring features include:

- Alarm notification through a red screen background, activation of an audible alarm, the switching of a remote alarm contact set, and the creation of an alarm log with time, date, and type of alarm.

- Alarm silence function on all parameters with up to 60 minutes of delay time (individually adjusted for each parameter). The alarm mode deactivates upon return to normal operating limits.

- Independent time delay action for each alarm parameter. Alarm action delays and audible alarm delays are each adjustable from 0 to 60 minutes in 1 minute increments. ‘Common alarm’ contacts activate after alarm action delay (Form C relay – N.O. and N.C. contacts provided).

Electrical/Control System

Our control panel is fully enclosed and wired in accordance with NEMA 1, NEC and UL/MET specifications. All control circuits and branch circuits are individually fuse protected. Solid state, “zero switching” outputs, for refrigeration and humidity control. Zero switching outputs prevent unnecessary radio frequency interference. The electrical system features include:

- Quick disconnect wiring for easy installation and removal of most mechanical and electrical assemblies.

- Detailed computer generated schematic provided with Operation Manual to aid in field servicing & troubleshooting.

CCS Touchscreen Control System

Microprocessor based I/O hardware with programmed logic running on Windows CE® platform. Features include:

- Control logic program is stored on a non-volatile, high capacity memory card EE-prom. All control parameter settings, alarms and setpoints are maintained during power failure, and restart is automatic upon power restoration.

- Conformance to the FDA 21 CFR 11 requirements for data recording, audit trails of controller settings modification, alarm history logs, operator event logs and secure file transfers. Operating data is encrypted and stored in user defined time length log files, and can be viewed on the touchscreen, or remotely by PC. Password protection provides multiple levels of user access and defined rights. Password aging and re-authentification for process changes are also provided per 21 CFR 11 specifications. High level encryption and digital signatures are supported for paperless operation.

- Real-time trending of temperature and humidity parameters and setpoints. The touchscreen provides auto-scaled and user definable scaled plots over a 1 minute to 12 hour time period. A ‘drag and zoom’ feature allows for magnified views within a specific plot period. The trend graphs can be printed by pressing an on-screen print icon and connecting an optional printer. Historical data logging is provided with the paperless recording option activated at the factory.

- Interface USB port for data transfer to printer or removable memory stick to maintain local ‘paper trail’ requirements. A touchscreen ‘print’ icon allows one touch printout of data trends in report or graphic format. The removable memory stick allows export and import of profiles, alarm files, audit trail files, and other data files. File utilities are available with the paperless recording option activated at the factory.

- Ethernet connectivity. This allows for remote viewing of chamber process variables and alarms through a web browser. These include: actual temperature, actual humidity, process setpoints, and system alarms with name and date/time of alarms. Data is “read only”, and the internal stored data cannot be altered.

Heating System

Supplemental heating is provided by a low watt density heating element encased in a stainless steel frame. The heat output is proportionally controlled between hot gas injection and the electric heater. Heating system features include:

- Nichrome wire duct style heater providing quick, accurate response.

- Modular plug-in element design for quick disconnect capability.

- Dual overtemp safeties provided for chamber, compressor and product protection.

- Adjustable electric heater on-delay. A percent-delay setting allows the electric heat to stage in earlier or later depending upon heat demand and control capability of the refrigeration hot gas. This feature ensures that the refrigeration system is efficiently used to control the chamber temperature, resulting in lower operating costs and steam usage when the chamber has humidity control.