Introduced in 1995, Agilent’s 1100 series HPLC system is an extremely popular HPLC. They are robust, durable, and versatile. The 1100 HPLC series supports efficient mixing and pulse-free pump action as well as advanced diagnostics and data analysis software. Many additional features include modular binary and quadrary pump configurations, a high speed proportioning valve, and pre-configured vacuum degasser, making the 1100 a high functioning reliable assett in the laboratory. The system is easy to use at a low cost.

This system includes:

- HP / Agilent 1100 Series G1315B DAD

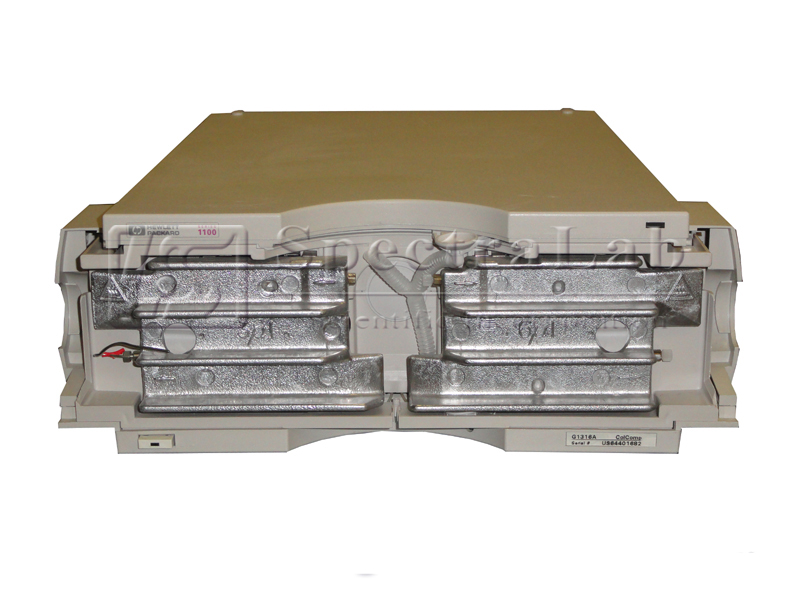

- HP / Agilent 1100 Series G1312A Binary Pump

- HP / Agilent 1100 Series G1329A Thermostated Autosampler

- HP / Agilent 1100 Series G1330A ALSTherm Sampler Chiller

- HP / Agilent 1100 Series G1316A Thermostated Column Compartment

- HP / Agilent 1100 Series G1322A Degasser

- HP / Agilent 1100 Series Solvent Tray

- PC with Suitable Software

This Agilent 1100 HPLC System is in great condition. It has been tested at SpectraLab Scientific.

A 90 day warranty is included.

Agilent 1100 Series HPLC System Manual PDFs

Performance Specifications

| G1315 Diode Array Detector | |

|---|---|

| Type | Specification |

| Detection type | 1024-element photodiode array |

| Light source | Deuterium and tungsten lamps |

| Wavelength range | 190 – 950 nm |

| Short term noise (ASTM) Single and Multi-Wavelength | ± 1 × 10-5 AU at 254 and 750 nm |

| Drift | 2 × 10-3 AU/hr at 254 nm |

| Linear absorbance range | > 2 AU (upper limit) |

| Wavelength accuracy | ± 1 nm |

| Wavelength bunching | 1 – 400 nm |

| Slit width | 1, 2, 4 , 8, 16 nm |

| Diode width | < 1 nm |

| Flow cells | Standard: 13 µl volume, 10 mm cell path length and 120 bar (1760 psi) pressure maximum Semi-Micro: 5 µl volume, 6 mm cell path length and 120 bar (1760 psi) pressure maximum High pressure: 1.7 µl volume, 6 mm cell path length and 400 bar (5880 psi) pressure maximum 500 nano: 0.5 µl volume, 10 mm cell path length and 50 bar (725 psi) pressure maximum |

| Control and data evaluation | Agilent ChemStation for LC |

| Analog outputs | Recorder/integrator: 100 mV or 1 V, output range 0.001 – 2 AU, two outputs |

| Communications | Controller-area network (CAN), GPIB, RS-232C, APG Remote: ready, start, stop and shut-down signals, LAN optional |

| Safety and maintenance | Extensive diagnostics, error detection and display (through control module and ChemStation), leak detection, safe leak handling, leak output signal for shutdown of pumping system. Low voltages in major maintenance areas. |

| GLP | Early maintenance feedback (EMF) for continuous tracking of instrument usage in terms of lamp burn time with user-settable limits and feedback messages. Electronic records of maintenance and errors. Verification of wavelength accuracy with built-in holmium oxide filter. |

| Housing | All materials recyclable. |

| G1312A Binary Pump | |

|---|---|

| Type | Specification |

| Hydraulic system | Two dual piston in series pumps with proprietary servo-controlled variable stroke drive, floating piston design and active inlet valve |

| Setable flow range | Setpoints 0.001 – 5 ml/min, in 0.001 ml/min increments |

| Flow range | 0.1 – 5.0 ml/min |

| Flow precision | < 0.3 % RSD (typically 0.15 %), based on retention time, at 1 ml/min |

| Pressure | Operating range 0 400 bar (0 – 5880 psi) up to 5 ml/min |

| Pressure pulsation | < 2 %amplitude (typically < 1 %), at 1 ml/min isopropanol, at all pressures > 1 MPa |

| Compressibility compensation | User-selectable, based on mobile phase compressibility |

| Recommended pH range | 1.0 – 12.5, solvents with pH < 2.3 should not contain acids which attack stainless steel |

| Gradient formation | High-pressure binary mixing, delay volume 180 – 480 µl without mixer, 600 – 900 µl with mixer, dependent on back pressure |

| Composition range | 1 – 99 % or 5 µl/min per channel, whatever is greater |

| Composition precision | < 0.2 % RSD, at 0.1 and 1 ml/min |

| Control and data evaluation | Agilent ChemStation for LC |

| Analog output | For pressure monitoring, 2 mV/bar, one output |

| Communications | Controller-area network (CAN), GPIB, RS-232C, AP |

| Safety and maintenance | Extensive diagnostics, error detection and display (through control module and Agilent ChemStation), leak detection, safe leak handling, leak output signal for shutdown of pumping system. Low voltages in major maintenance areas. |

| GLP features | Early maintenance feedback (EMF) for continuous tracking of instrument usage in terms of seal wear and volume of pumped mobile phase with user-settable limits and feedback messages. Electronic records of maintenance and errors. |

| Housing | All materials recyclable. |

| G1329A Thermostated Autosampler (100 µl metering head) | |

|---|---|

| Type | Specification |

| GLP features | Early maintenance feedback (EMF), electronic records of maintenance and errors |

| Communications | Controller-area network (CAN). GPIB (IEEE-448), RS232C, APG-remote standard, optional four external contact closures and BCD vial number output |

| Safety features | Leak detection and safe leak handling, low voltages in maintenance areas, error detection and display |

| Injection range | 0.1 – 100 µl in 0.1 µl increments Up to 1500 µl with multiple draw (hardware modification required) |

| Replicate injections | 1 – 99 from one vial |

| Precision | Typically < 0.5 % RSD of peak areas from 5 – 100 µl, typically < 1 % RSD of peak areas from 1 – 5 µl |

| Minimum sample volume | 1 µl from 5 µl sample in 100 µl microvial, or 1 µl from 10 µl sample in 300 µl microvial |

| Carryover | Typically < 0.1 %, < 0.05 % with external needle cleaning |

| Sample viscosity range | 0.2 – 50 cp |

| Replicate injections per vial | 1 – 99 |

| Sample capacity | 100 × 2-ml vials in 1 tray 40 × 2-ml vials in ½ tray 15 × 6-ml vials in ½ tray (Agilent vials only) |

| Injection cycle time | Typically 50 s depending on draw speed and injection volume |

| G1329A Thermostated Autosampler (900 µl metering head) | |

|---|---|

| Type | Specification |

| Pressure Operating range | 0-20 MPa (0-200 bar, 0-2950 psi) |

| GLP features | Early maintenance feedback (EMF), electronic records of maintenance and errors |

| Communications | Controller-area network (CAN). GPIB (IEEE-448), RS232C, APG-remote standard, optional four external contact closures and BCD vial number output |

| Safety features | Leak detection and safe leak handling, low voltages in maintenance areas, error detection and display |

| Injection range | 0.1 – 900 µl in 0.1 µl increments (recommended 1 µl increments) Up to 1800 µl with multiple draw (hardware modification required) |

| Replicate injections | 1 – 99 from one vial |

| Precision | Typically < 0.5% RSD of peak areas from 5 – 2000 µl, typically < 1% RSD of peak areas from 2000 – 5000 µl, Typically < 3% RSD of peak areas from 1 – 5 µl |

| Minimum sample volume | 1 µl from 5 µl sample in 100 µl microvial, or 1 µl from 10 µl sample in 300 µl microvial |

| Carryover | Typically < 0.1%, < 0.05% with external needle cleaning |

| Sample viscosity range | 0.2 – 50 cp |

| Sample capacity | 100 × 2-ml vials in 1 tray 40 × 2-ml vials in ½ tray 15 × 6-ml vials in ½ tray (Agilent vials only) |

| Injection cycle time | Typically 50s depending on draw speed and injection volume |

| G1316A Thermostated Column Compartment | |

|---|---|

| Type | Specification |

| Temperature range | 10 degrees below ambient to 80 °C |

| Temperature stability | ± 0.15 °C |

| Temperature accuracy | ± 0.8 °C ± 0.5 °C |

| Column capacity | Three 30 cm |

| Warm-up/cool-down time | 5 minutes from ambient to 40 °C 10 minutes from 40 – 20 °C |

| Dead volume | 3 µl left heat exchanger 6 µl right heat exchanger |

| Dimensions (h × w × d) | 140 × 410 × 435 mm |

| Weight | 10.2 kg |

| Communications | Controller-area network (CAN), GPIB, RS-232C, APG Remote: ready, start, stop and shut-down signals, LAN optional |

| Safety and maintenance | Extensive diagnostics, error detection and display (through control module and Agilent ChemStation), leak detection, safe leak handling, leak output signal for shutdown of pumping system. Low voltages in major maintenance areas. |

| GLP features | Column-identification module for GLP documentation of column type |

| Housing | All materials recyclable |

| G1322A Degasser | |

|---|---|

| Type | Specification |

| Maximum flow rate | 10 ml/min per channel |

| Number of channels | 4 |

| Internal volume per channel | Typically 12 ml per channel |

| Materials in contact with solvent | PTFE, PEEK |

| pH range | 1 – 14 |

| Analog output (AUX) | For pressure monitoring, range 0 – 3V |