Varian, Inc.\’s CP-4900 is a rugged, compact, lab-quality analyzer that always delivers the information you need – at any site. When the composition of gas mixtures is critical, this 4th generation micro-Gas Chromatograph generates more data in less time for faster, better business decisions.

The CP-4900 offers advanced micro-machining and computing technologies and one to four plug-and-play GC channels. Each channel is a separate GC with pneumatics, injector, column, and detector. Low power consumption lets you take your GC to the sample source.

Fast, Reliable Answers

Precise, cost efficient gas chromatography analysis in seconds

- Natural gas

- Refining

- Specialty gases

- Fuel cells

- Oil and gas exploration

- Any area where precise gas analysis saves money and adds value!

Ready to use immediately

- The CP-4900 arrives configured for your analysis

- Modular design for fast maintenance

- Flash memory for quick software upgrades via the internet

- Reconfigure for new applications in five minutes with user-installed plug-and-play GC channels

Take the CP-4900 with you

- Weighing from 5.2 kg and just 15 cm wide, the CP-4900 is easy to move

- Optional Field Case with gases and battery power for remote locations

- Start analyses within 15 minutes of power-up

- Laptop PC control of all instrument parameters and data handling

Local or remote control of operation and data reduction

- Choose either Varian\’s Star Chromatography Workstation or CP-Maître Elite for error-free operation

- Standard or custom reports with minimal operator intervention

- Monitor results to set limits, activate alarms, or switch valves

- Standard 4-20 mA signal readout for process control

- Communicate with the CP-4900 from a process control computer via industry-standard RS232, RS485, or Ethernet protocol

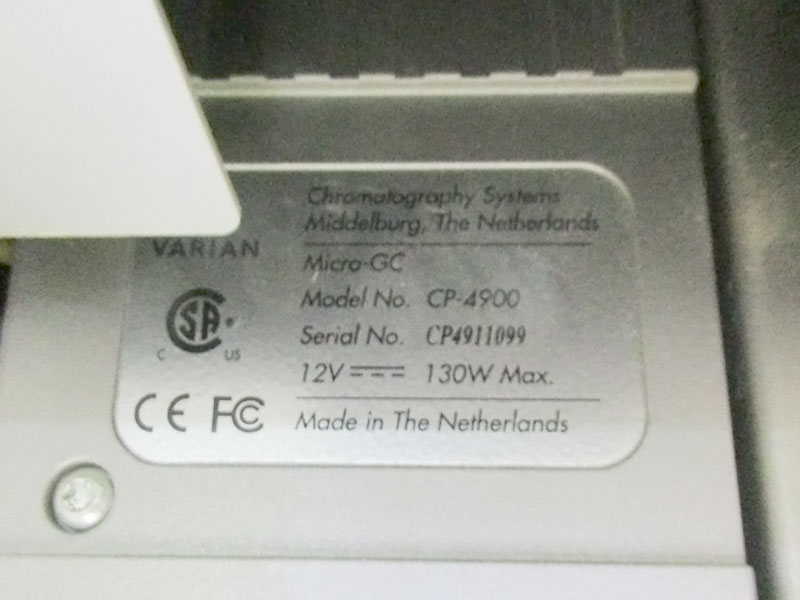

Specifications

CP-4900 GC Specifications

Configuration: one to four plugand-play GC channels

Control: independent control for each channel with its separate pneumatics, injector, column, and detector

Injector

Micro-machined injector with no moving parts

Injection volume: 1 µL to 10 µL, software selectable

Optional heated injector: 30 °C to 110 °C, including heated transfer line

Column Oven

Temperature range: 30 °C to 180 °C, isothermal

Optional backflush capability

Detector

Micro-machined Thermal Conductivity Detector (TCD)

Dual-channel (sample and reference)

Internal volume: 200 nL per channel

Filaments: 4

Detection Limits

WCOT columns: 1 ppm

Micro-packed columns: 10 ppm

Operating Range

Concentration: 1 ppm to 100% level

Linear dynamic range: 106

Repeatability: < 0.5% RSD for propane at 1 mol % level for WCOT columns at constant temperature and pressure

Carrier Gas

He, H2, N2 or Ar: 550 ± 10 kPa (80 ± 1.5 psig) input

Inlet connection: 3.2 mm (1/8 in.) stainless steel compression fitting (Swagelok)

Sampling

Sample inlet: 1.6 mm (1/16 in.) stainless steel Valco® fitting with replaceable 5 µm stainless steel filter

Sample conditions: noncondensing gas of 0 °C to 40 °C

Maximum sample input pressure: 200 kPa (29 psig)

Optional separate sample inlet in front or back

Environmental Requirements

Humidity (relative): 0% to 95% non-condensing

Temperature: 0 °C to 50 °C

Dimensions and Weight

Two-channel system: 28 cm (h) x 15 cm (w) x 30 cm (d)

Four-channel system: 28 cm (h) x 15 cm (w) x 55 cm (d)

Weight: minimum of 5.2 kg

Power Requirements

Main power: 90-130 Vac or 180-260 Vac, 50-60 Hz

Output: 12 Vdc, maximum 180W

Communication

Analog input: 6 signals

External port: RS-232

Optional: Ethernet TCP/IP with static IP address

Optional: Com Port for external devices, selectable RS-232 or RS-485

Control/Data Handling Software

Standard packages: Star Chromatography Workstation or CP Maître-Elite

Regulatory compliance and reports: meet requirements, particularly for the natural gas and petrochemical industries

Special packages: ISOCAL and BTU for natural gas properties, such as

calorific value and relative density, meet ISO 6976, GPA 2171, and ASTM D 3588 standards Optional Field Case

Gas containers: one or two 300 mL gas containers with maximum pressure of 12,000 kPa (1740 psig)

Rechargeable battery packs: two

Two-channel system: 37 cm (h) x 29 cm (w) x 41 cm (d)

Four-channel system: 37 cm (h) x 29 cm (w) x 72 cm (d)

Weight with CP-4900: minimum of 16 kg

Optional Micro-Gasifier

Heated pressure reducing regulator

Injection of high pressure LPG or LNG samples